Case Study

Philadelphia Gear® Rebuild Helps Modernize Water Facility

The Primary Challenge

Water and wastewater utilities are crucial to providing clean, easily accessible water for people globally. One utility commission in Maryland delivers clean water and responsibly manages wastewater for nearly 2 million residents in a major suburban area. This is accomplished through a network of five water stations and 11,600 miles of pipeline spanning nearly 1,000 square miles.

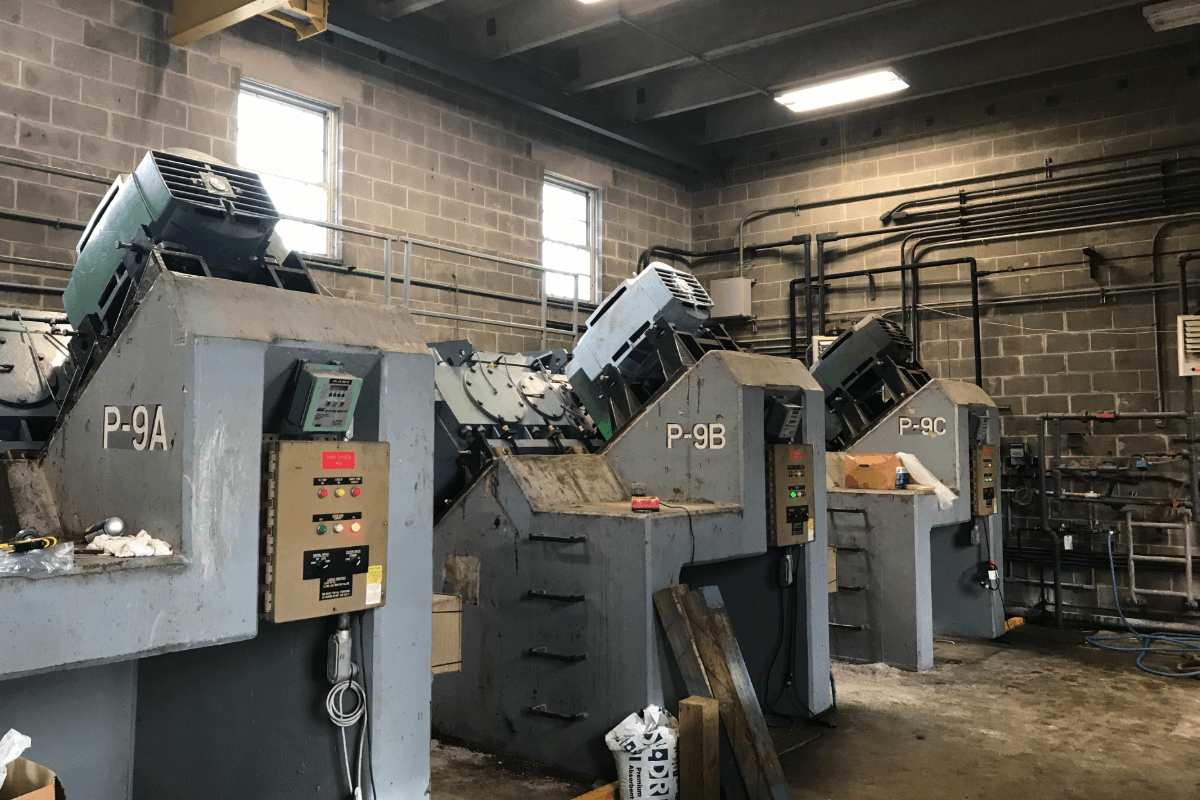

One of the utility commission’s water stations used a set of seven Archimedes screw pumps, with each screw operating intermittently. The screws were driven by five Philadelphia Gear® gearboxes and two non-Philadelphia Gear brand gearboxes installed in 1994 by the engineering firm that designed the station. After over 25+ years of service, several gearboxes experienced repeat failure despite multiple repairs and rebuilds by a competitor’s facility.

While onsite at the request of the water station’s reliability engineer, Philadelphia Gear experts listened to the customer’s problem and discovered that the root cause was not gearbox-related after all. It turned out that each gear drive rested on mounting bars that were affixed to a concrete baseplate that was missing Chockfast®, a synthetic quick-set concrete that helps stabilize the equipment and support its weight. This led to settling, called soft foot, that resulted in twisted gear housings, misalignment, and uneven wear on all of the gearing.

“Chockfast should have been used during the initial installation and reinforced every time a gearbox was removed for repairs and reinstalled. But that wasn’t what happened,” said Steve Dyal, territory account representative at Philadelphia Gear, a part of Timken Power Systems. “The customer was impressed with our field service engineering and appreciated that we identified the root cause so quickly. They immediately asked us to help solve the problem for good.”

The Solution

In addition to pinpointing the root cause of the damage, Philadelphia Gear provided pump gearbox repair services to all five Philadelphia Gear gearboxes and completely replaced the two competitor gearboxes. All work was performed at Philadelphia Gear’s Delaware Service Center in New Castle, Del.

Each repaired gearbox was thoroughly inspected to determine specific damage and repair needs, which ranged from bearing and seal replacement to more complex rebuilds requiring new pinions, gears, and shafts. All repaired units underwent a two-hour spin test to measure vibration and bearing temperatures before being returned to the customer for reinstallation.

To replace the non-Philadelphia brand gearboxes, Philadelphia Gear’s technical experts reverse-engineered the units and then enhanced the designs to improve equipment performance, reliability, and life. These enhancements included an improved gear mesh that helps reduce noise and premature wear, all of which extend the lifecycle of the gears.

Key Results

The water station’s maintenance team applied Chockfast to support the mounting bars and all repaired and new gearboxes, preventing future damage due to soft foot settling. Over a period of seven years, the customer affordably upgraded its entire series of Archimedes screw pump gearboxes. The repairs generated significant savings over purchasing all new units.

Philadelphia Gear and the customer have also formed a strong relationship, leading to projects at one of the utility commission’s other wastewater treatment facilities. Philadelphia Gear is providing gearbox repair, line shaft repair, equipment removal, and installation of a new agitator-mixer gearbox at that location.

“As a technical solution provider, we want to solve customer challenges completely the first time,” said Dyal. “The quicker we get to the root cause, the faster we can deliver products and services that will reduce maintenance, improve uptime, and save money over the long run. It’s all about what’s best for the customer.”