Your artificial intelligence data centers demand quick-deploy energy infrastructure and dependable power. Some manufacturers are years behind schedule — but Philadelphia Gear has gearbox solutions ready to power data centers today.

Over 100 years of power generation performance

For more than a century, Philadelphia Gear has manufactured, refurbished, and serviced gearboxes for heavy-duty Frame 5, 6, 7, and 9 GE turbines. Industry-leading gas, coal, hydroelectric, wind, and nuclear power plant operators trust our custom solutions to ensure continuous, high-load power delivery — without unexpected downtime.

That’s because they’ve discovered the Philadelphia Gear difference:

- Industry-leading warranties

Five years on new and replacement gearboxes, and three years on gearbox repairs - 24/7 Onsite Technical Support

Get expert service and repair for your data center gearboxes in any application - Full lifecycle solutions

Ranging from new designs and upgrades to emergency repairs and rebuilds - American-made gearboxes

Designed, built, and supported at one of seven locations spanning the United States - Timken Power Systems network support

Including services for electric motors and generators, bearings, controls systems, and switchgears

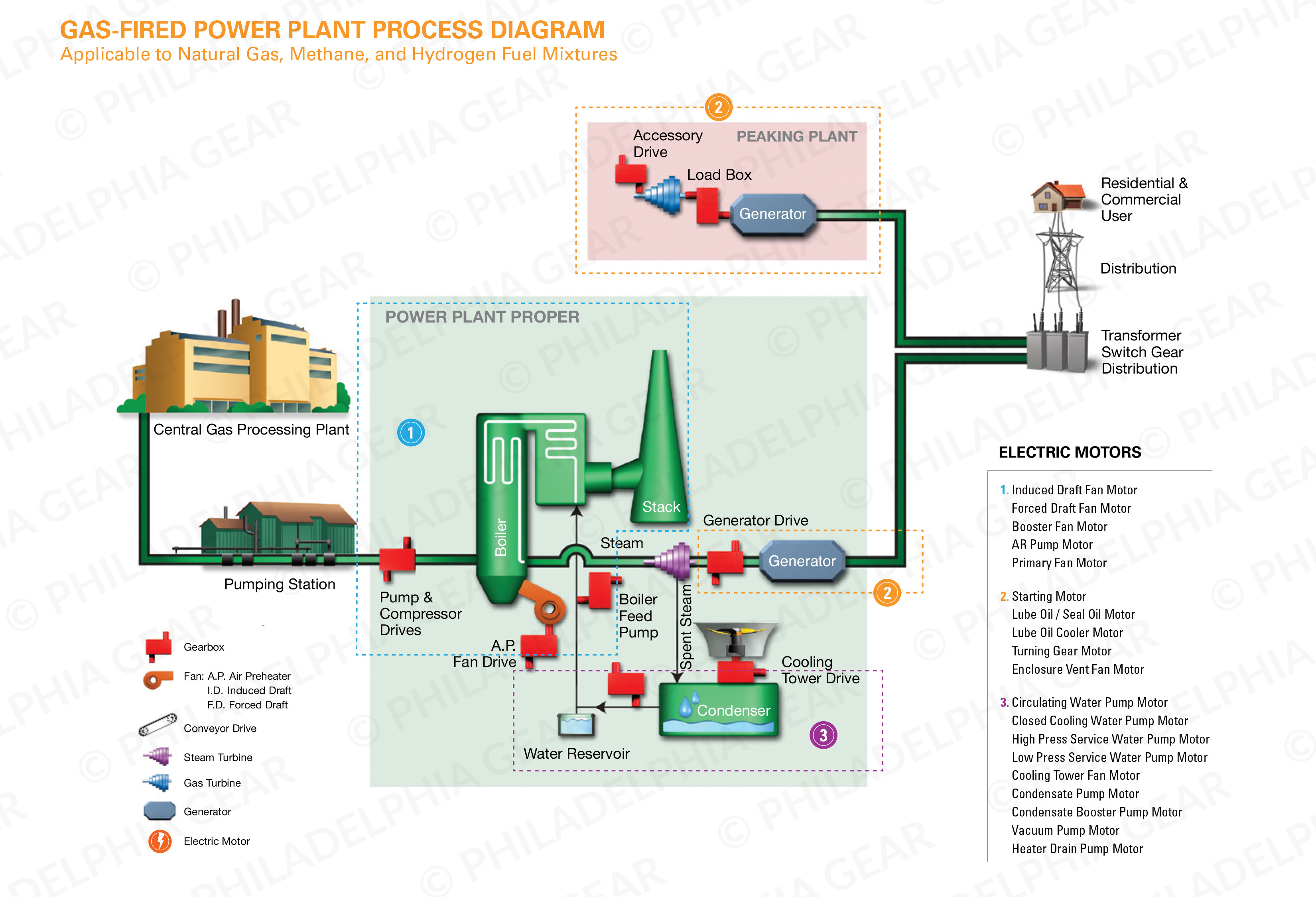

Solutions for reliable gas-fired power

Philadelphia Gear delivers a broad range of motor, gear, and drive solutions to ensure dependable gas-fired generation.

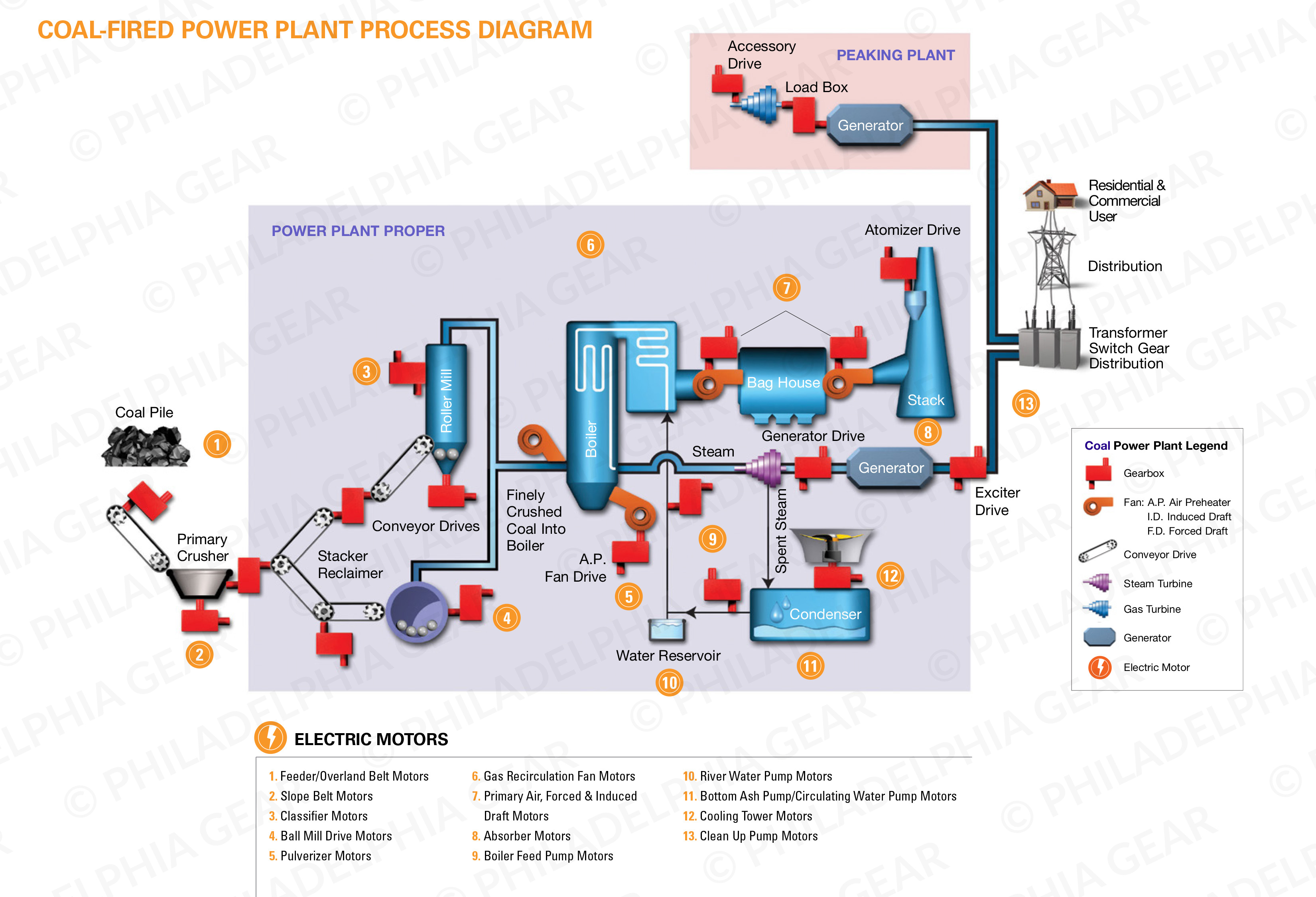

Solutions for proven coal-fired power

For over 100 years, Philadelphia Gear has helped deliver uninterrupted coal-fired power with a wide range of proven solutions.

Accelerate AI power generation with Philadelphia Gear

Don’t put AI power projects on hold waiting for backlogged gearbox manufacturers. Philadelphia Gear’s engineers will meet your build parameters — new fabrication or turbine repurposing — to accelerate your project timelines and get your AI facilities ready, faster.

We work in lockstep with your team at any stage of planning to help you:

- Custom-engineer gearboxes for any turbine configuration

- Retrofit legacy systems with updated, high-efficiency gearing

- Accelerate and meet urgent timelines, thanks to U.S.-based manufacturing facilities

- Get one-stop access to complete drivetrain solutions, saving time and money

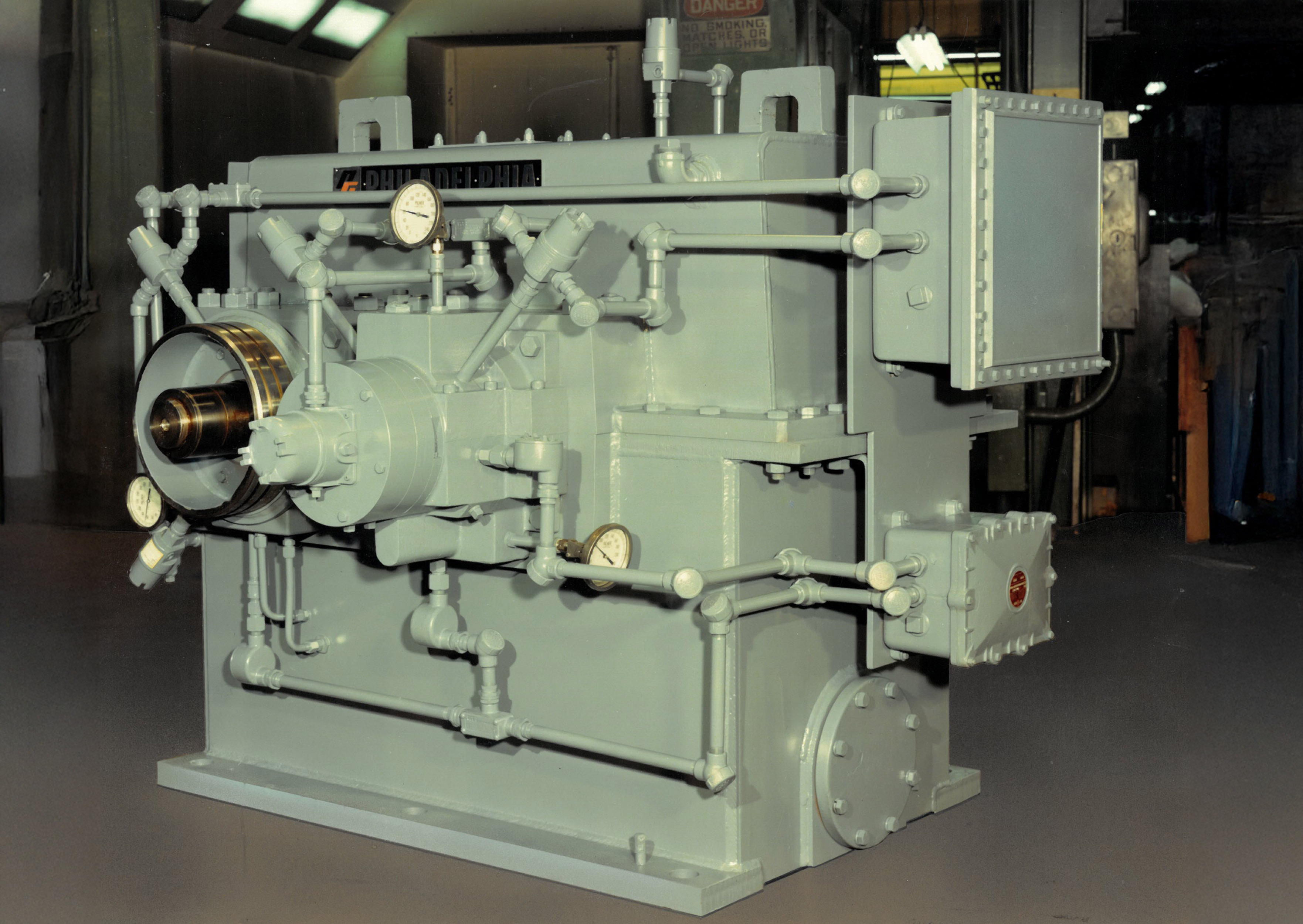

OUR GEARBOX BUILDS & REBUILDS

|

|

|

|

|

|

Trusted by top power generation companies

See what end-to-end service looks like, inside and out

Discover how Philadelphia Gear and Timken Power Systems bring unmatched expertise and support to your industrial drivetrain, including industrial gearbox repair, electric motor maintenance, bearings, and complete drivetrain repair.

EXPLORE POWER GENERATION RESOURCES

Case Studies

PROVEN SOLUTIONS FOR YOUR COMPLETE DRIVETRAIN SYSTEMPhiladelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1

Gear drive repair

-

2

New and replacement gear drive expertise

-

3

Gear drive replacement parts

-

4

Onsite technical services

-

5

Drivetrain solutions

1 Gear drive repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gear drive expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gear drive replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business — our experts come to your location. Explore gear drive installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Philadelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1Gear drive repair

-

2New and replacement gear drive expertise

-

3Gear drive replacement parts

-

4Onsite technical services

-

5Drivetrain solutions

1 Gear drive repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gear drive expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gear drive replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business — our experts come to your location. Explore gear drive installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Speed up your AI data center project. Talk to Philadelphia Gear today.Reach out to our experts to get an AI data center power solution that works — and stays running reliably.

CONTACT US

Reach out to our experts to get an AI data center power solution that works — and stays running reliably.