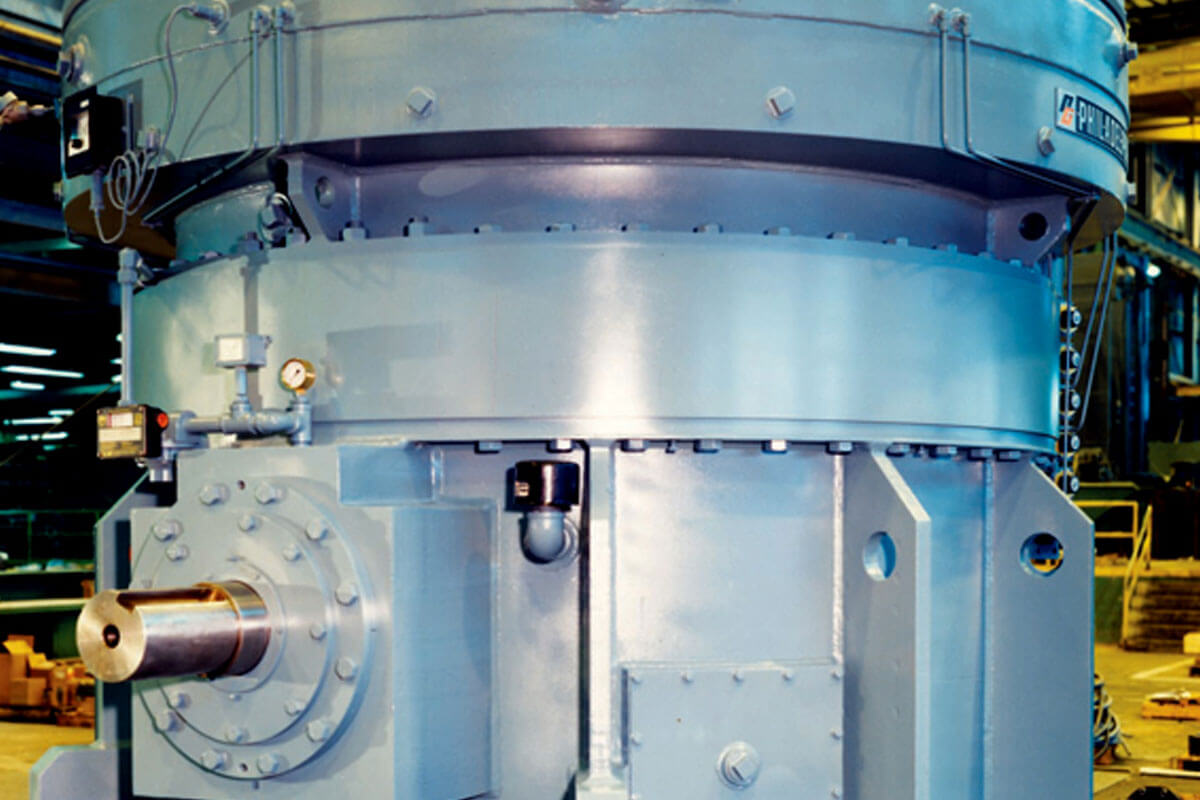

When the world’s leading OEMs and government agencies need mission-critical gearbox performance, they choose Philadelphia Gear®. Our experts have manufactured some of the highest torque industrial gearboxes ever created, complete with proven track records: millions of operational hours, low maintenance costs, and high availability rates that are second to none.

From Philadelphia Gear’s beginnings over 130 years ago, we’ve served as the designer of record for clients including ABB, B&W, GE, the Army Corps of Engineers, NASA, and the US Navy and Coast Guard. With our experience and ongoing innovation, there is virtually no low-speed gearbox application for which we haven’t created a trusted solution.

OUR PROMISE: GET MORE FROM YOUR MISSION-CRITICAL EQUIPMENT Our team of specialists is dedicated to supporting your operations in five ways:

-

1

Smarter design

-

2

Faster production

-

3

Durable solutions

-

4

Stronger service

-

5

Local access

1 Smarter design

We have a full staff of experienced engineers at each of our sites and our main office and technical center outfitted with the most sophisticated design software. We leverage centuries of combined expertise to create a smarter design and get the job done right.

2 Faster production

We continuously invest in the improving our equipment to stay at the forefront of gear design and manufacturing. We leverage this superior technology with lean manufacturing techniques to minimize production time.

3 Durable solutions

Philadelphia Gear has a long-standing reputation of superior quality. Our industrial gearboxes have been proven to stand some of the harshest environments, operating with very minimal maintenance for decades, maximizing your equipment lifecycle with products that last.

4 Stronger service

We believe so much in superior service that we’ve built a whole department that’s dedicated to running to the problem. Our Onsite Technical Services team is there to support our customers with 24/7 field service expertise so we’re there anytime you need us.

5 Local access

We’ve built a network of regional service facilities to stay close to our customers so we can offer some of the fastest service in the industry. Not only can we offer local gear repair, we can leverage the expertise of our motor repair facilities to expand our capabilities to full electro-mechanical support.

Our team of specialists is dedicated to supporting your operations in five ways:

-

1Smarter design

-

2Faster production

-

3Durable solutions

-

4Stronger service

-

5Local access

1 Smarter design

We have a full staff of experienced engineers at each of our sites and our main office and technical center outfitted with the most sophisticated design software. We leverage centuries of combined expertise to create a smarter design and get the job done right.

2 Faster production

We continuously invest in the improving our equipment to stay at the forefront of gear design and manufacturing. We leverage this superior technology with lean manufacturing techniques to minimize production time.

3 Durable solutions

Philadelphia Gear has a long-standing reputation of superior quality. Our industrial gearboxes have been proven to stand some of the harshest environments, operating with very minimal maintenance for decades, maximizing your equipment lifecycle with products that last.

4 Stronger service

We believe so much in superior service that we’ve built a whole department that’s dedicated to running to the problem. Our Onsite Technical Services team is there to support our customers with 24/7 field service expertise so we’re there anytime you need us.

5 Local access

We’ve built a network of regional service facilities to stay close to our customers so we can offer some of the fastest service in the industry. Not only can we offer local gear repair, we can leverage the expertise of our motor repair facilities to expand our capabilities to full electro-mechanical support.

THOROUGHLY INSPECTED - AND GUARANTEED

We inspect, measure, and check every housing and element that goes into our gearboxes, documenting it all in an exhaustive paper trail. All materials are certified to our current standards, vacuum degassed, and ultrasonically tested, followed by cleanliness and mechanical testing based on your application.

Once an industrial gearbox is ready for shipping, you get ISO documentation of our procedures, plus our industry-leading five-year warranty. The result? A painstakingly engineered, manufactured, and vetted gearbox guaranteed to keep your operations moving.