Case Study

Using creative engineering to restore service to coal-fired power plant

The Northeast Regional Service Center received an emergency call from plant technicians at a large coal-fired power plant located in the Northeast Region of the United States. The plant experienced excessive vibration levels in a high-speed gearbox that was driving their boiler feedwater pump. In service since the 1960s, the gearbox, a non Philadelphia Gear brand, operates a high capacity pump that feeds water to a boiler that produces pressurized steam used in generating electricity

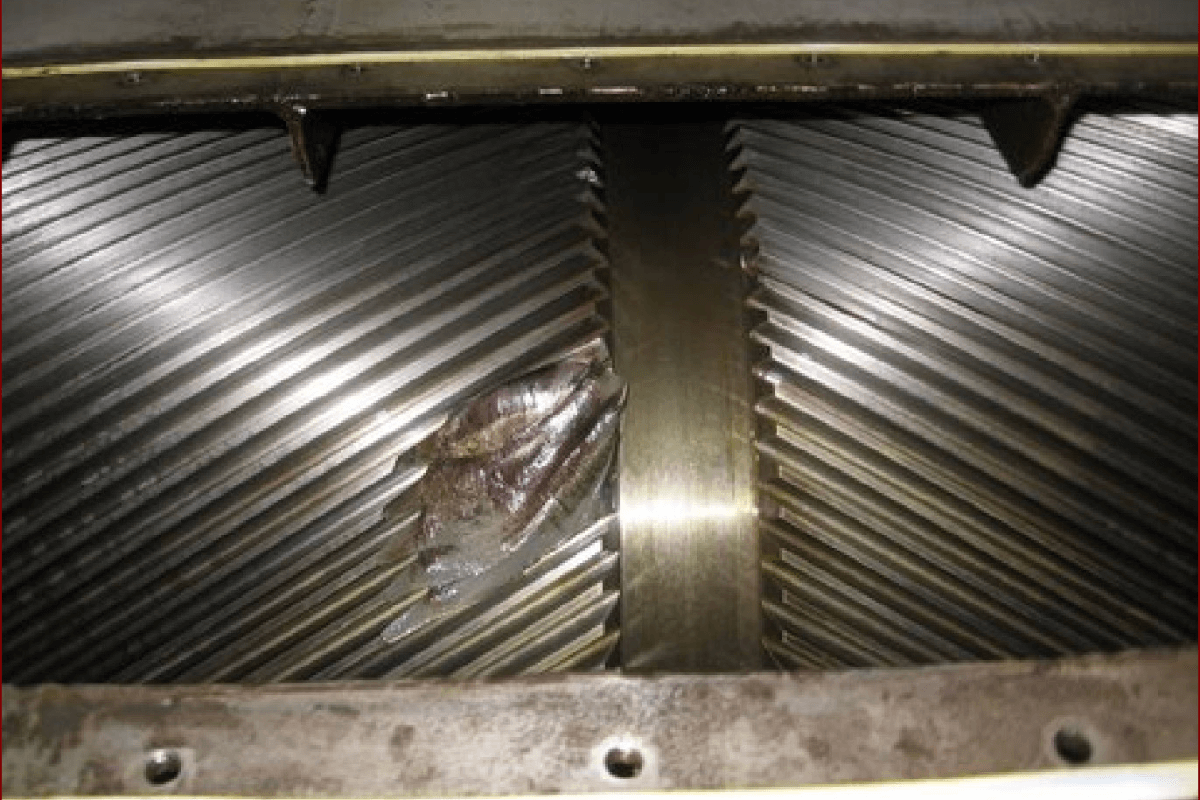

Technicians from the Delaware facility were called on-site to inspect the gearbox. Upon visual examination, the cause of the vibration became apparent when they found that a large chunk of gear tooth had broken free (due to a subsurface crack that developed from years of fatigue), resulting in an out-of-balance condition.

Years prior to the breakdown, the plant had Philadelphia Gear manufacture a spare gearset for the pump drive. When plant maintenance personnel attempted to install the spare with help from a Delaware field technician, they could not achieve the proper gear mesh. It turns out that the housing bores that held the gear shafts were not parallel, causing a misalignment and improper tooth contact. To verify that the gears were not improperly manufactured, they were sent to the Delaware Regional Service Center for evaluation. The shop took measurements and tested the gears on a roll stand, and proved that they were the correct geometry and achieved the proper tooth contact.

Eliminating the possibility of faulty manufacturing, the plant shipped the entire gearbox to the service center for emergency repair. Delaware’s engineering team was challenged to develop a solution to fix the alignment issue without procuring a new housing, which could take anywhere from eight to 12 weeks, a period of time which the plant could not wait. The misaligned housing bores on the gearbox were inspected and determined to be in good condition, so engineers came up with a plan to machine a new set of bearings in an eccentric shape, which would offset the gear shafts held by the housing bores and compensate for the misalignment, thereby restoring the proper tooth contact.

Tackling that problem, the team also designed a series of upgrades at the request of the customer. Provisions were made in the housing to accommodate probes used for condition monitoring, and new lifting eyes were manufactured to replace an underrated, aging set. The final design issue involved an unorthodox drainage system connected to the drive. The original housing had an oil drain line welded to its bottomhalf, which was cut with a torch during the time when the gearbox was uninstalled. The engineering team designed a new drain line to identical specifications and installed it in the same position to avoid installation issues.

Once complete, the service center deployed a field technician to help assist with the alignment and installation of the gearbox. It turns out all of the design modifications were a success.

The housing bores were now parallel and in alignment, and the proper tooth contact on the gearset was achieved. The unit was restarted and brought back into service only two weeks after receiving the initial call.