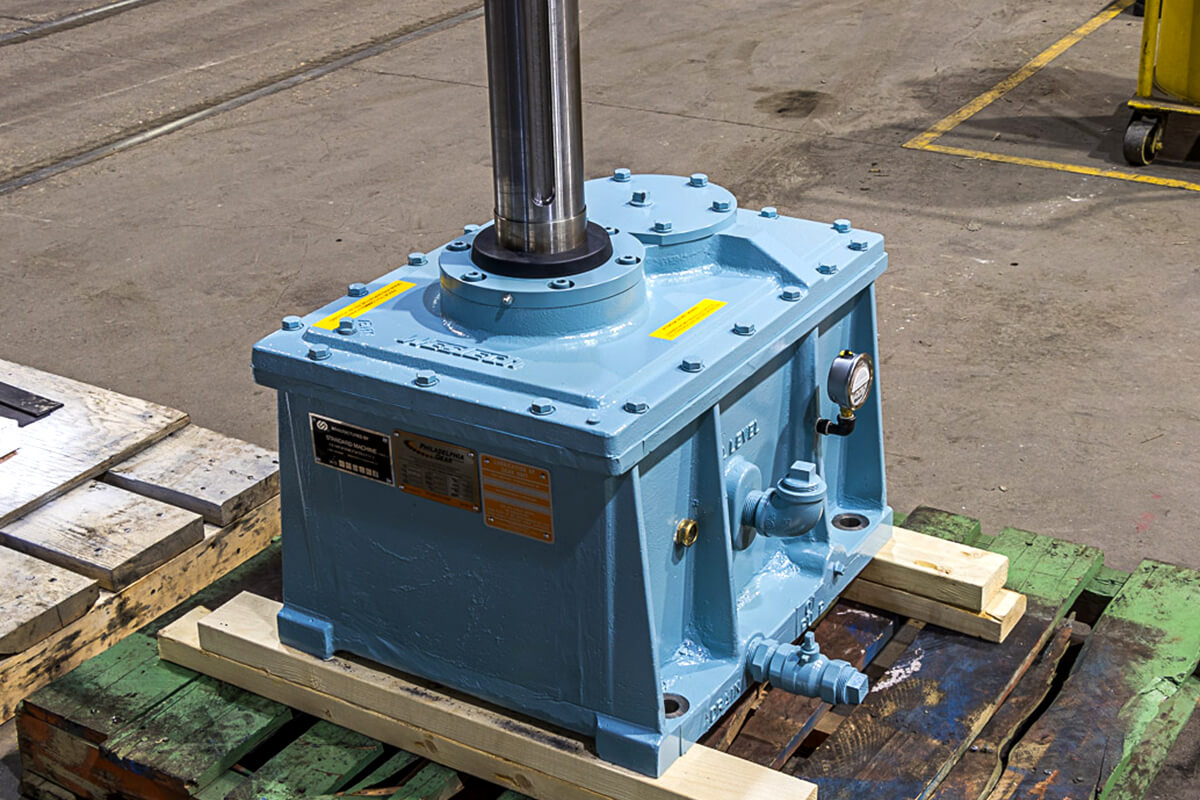

Get your industrial gearbox and industrial equipment running reliably with customized industrial gear repair from Philadelphia Gear®. With over 130 years of industry-spanning expertise, we set the bar for trusted industrial gearbox repair – even for non-Philadelphia Gear products. Our complete gear strategy approach ensures every repair aligns with long-term performance, reliability, and lifecycle goals.

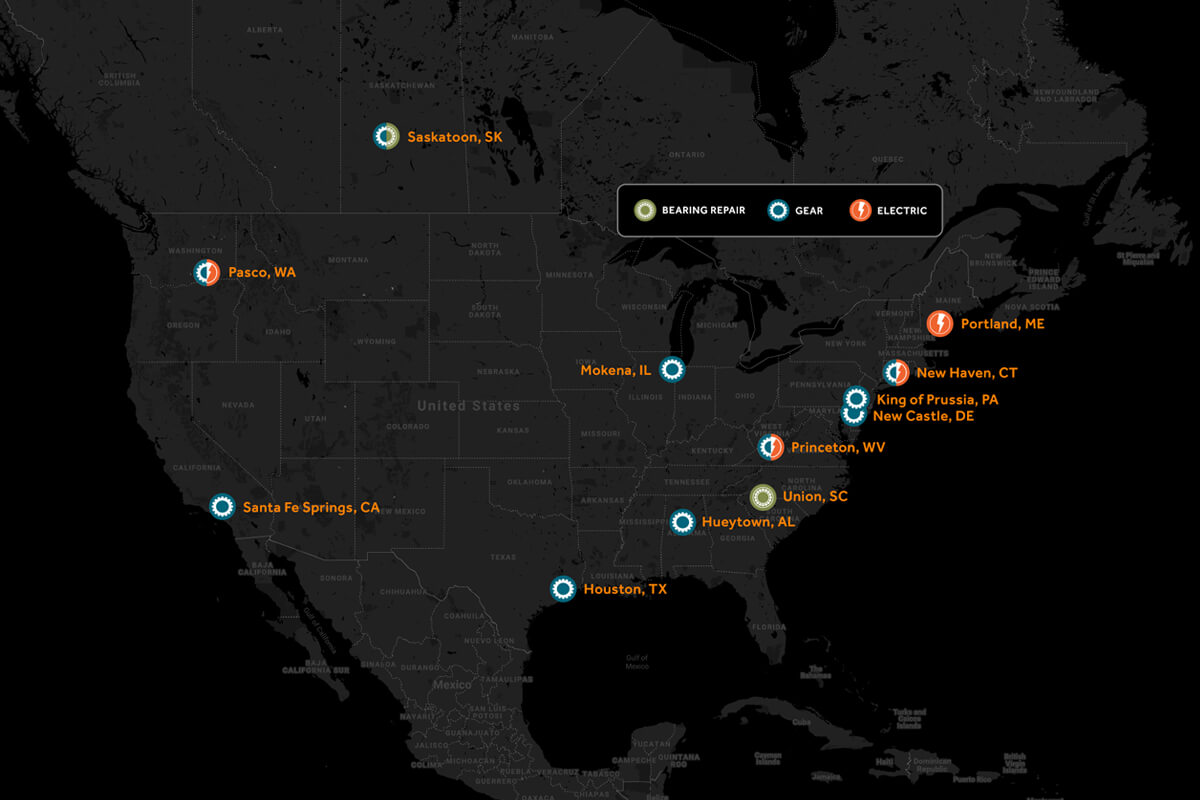

Our expert technicians leverage a multi-step industrial gear repair, rebuild, and overhaul process to return equipment to its optimal performance. Our five regional service and manufacturing facilities invest in state-of-the-art equipment to support competitor brands’ products. And with reverse engineering capabilities, we can record exact measurements, then produce component parts to original specifications – duplicating virtually any configuration, gear, or gearbox.

No matter the industry—whether power generation, oil and gas, mining, or marine—Philadelphia Gear® delivers precision repair solutions that meet the highest standards of quality and reliability. Our team understands the urgency of minimizing downtime, which is why we offer rapid response, detailed failure analysis, and tailored repair strategies for each gearbox, including sourcing or manufacturing industrial gearbox parts for critical components. Every repair is backed by rigorous testing and inspection protocols, ensuring your equipment returns to service with extended life and enhanced performance.

TERMS AND CONDITIONS

Our Industrial Gearbox Repair Process

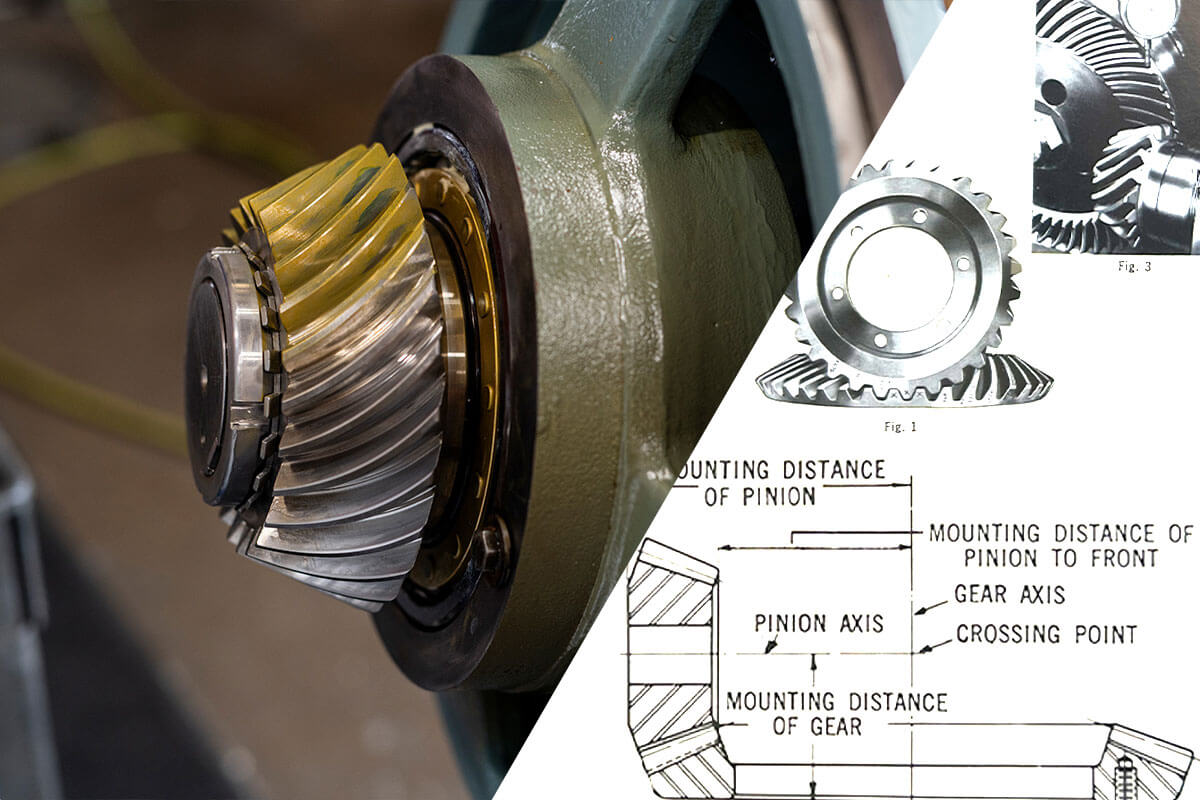

Philadelphia Gear delivers industrial gearbox repair through a rigorous, multi-stage process designed to restore equipment to peak performance with precision and reliability. Our expert technicians begin with a comprehensive inspection, using advanced diagnostic tools to assess component wear and operational issues, ensuring thorough industrial gear repair. This is followed by meticulous disassembly, cleaning, and precise measurement of all parts to identify defects. We apply state-of-the-art machining, gear grinding, heat treatment, and custom fabrication to restore or upgrade components to meet or exceed original specifications. Each gearbox undergoes extensive spin testing and quality assurance checks before being painted, preserved, and shipped. This structured approach, combined with our reverse engineering expertise, minimizes downtime and ensures long-lasting results for industries like power generation, mining, and marine

Types of Industrial Gears We Repair

Philadelphia Gear excels in industrial gear repair, servicing a wide range of gearbox equipment to meet diverse industrial needs with unmatched versatility. Our industrial gearbox repair expertise spans parallel shaft gearboxes for high-torque power transmission, right-angle bevel gearboxes for compact drive systems, and planetary gearboxes for precision-heavy applications like wind turbines and heavy machinery. We also handle worm gearboxes for high-reduction needs, speed increasers for specialized processes, speed reducers, and open gearing systems for large-scale milling. Whether it’s a pump gearbox, hydroviscous clutch, or custom drive system, our ISO-certified facilities are equipped to deliver repairs that meet stringent performance standards, ensuring extended service life across sectors like oil and gas and marine propulsion

Non-Philadelphia Gear Gearbox Brands We Repair

At Philadelphia Gear, our industrial gearbox repair capabilities extend to virtually any gearbox brand, making us a trusted partner for comprehensive industrial gear repair across a wide array of manufacturers. Our technicians are skilled in servicing gearboxes from industry leaders such as Falk, Lufkin, Flender, Siemens, and Sumitomo, as well as legacy brands like Western Gear, Hamilton Gear, and D.O. James. We also support specialized systems from Marley, Renk, and Maag, ensuring compatibility with both modern and obsolete designs. Using advanced reverse engineering and precision manufacturing, we replicate or enhance industrial gearbox parts and other components to exact specifications, delivering reliable repairs for non-Philadelphia Gear products. This broad brand support, backed by our three-year warranty, ensures seamless integration and peak performance for clients in power generation, mining, and other heavy industries.

KEEP YOUR OPERATIONS RUNNING SMOOTHLY. CONTACT PHILADELPHIA GEAR TODAY. We’re standing by to help with your most complex industrial gearbox repair challenges. Our specialists use a proven gear strategy roadmap to ensure your equipment receives the most effective repair or rebuild solution. Connect with one of our expert specialists today for industrial gear repair and gearbox rebuild services.

CONTACT US

We’re standing by to help with your most complex industrial gearbox repair challenges. Our specialists use a proven gear strategy roadmap to ensure your equipment receives the most effective repair or rebuild solution. Connect with one of our expert specialists today for industrial gear repair and gearbox rebuild services.