Get virtually infinite speed control with variable speed clutches from Philadelphia Gear®.

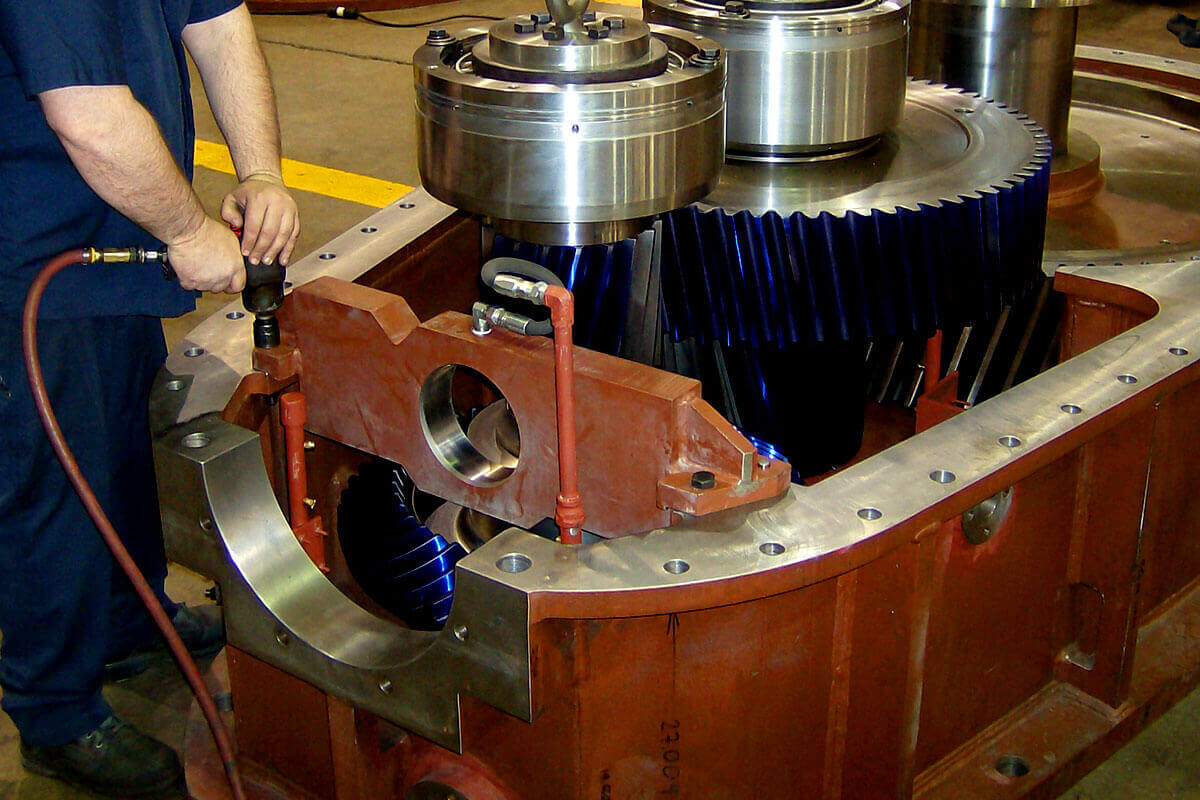

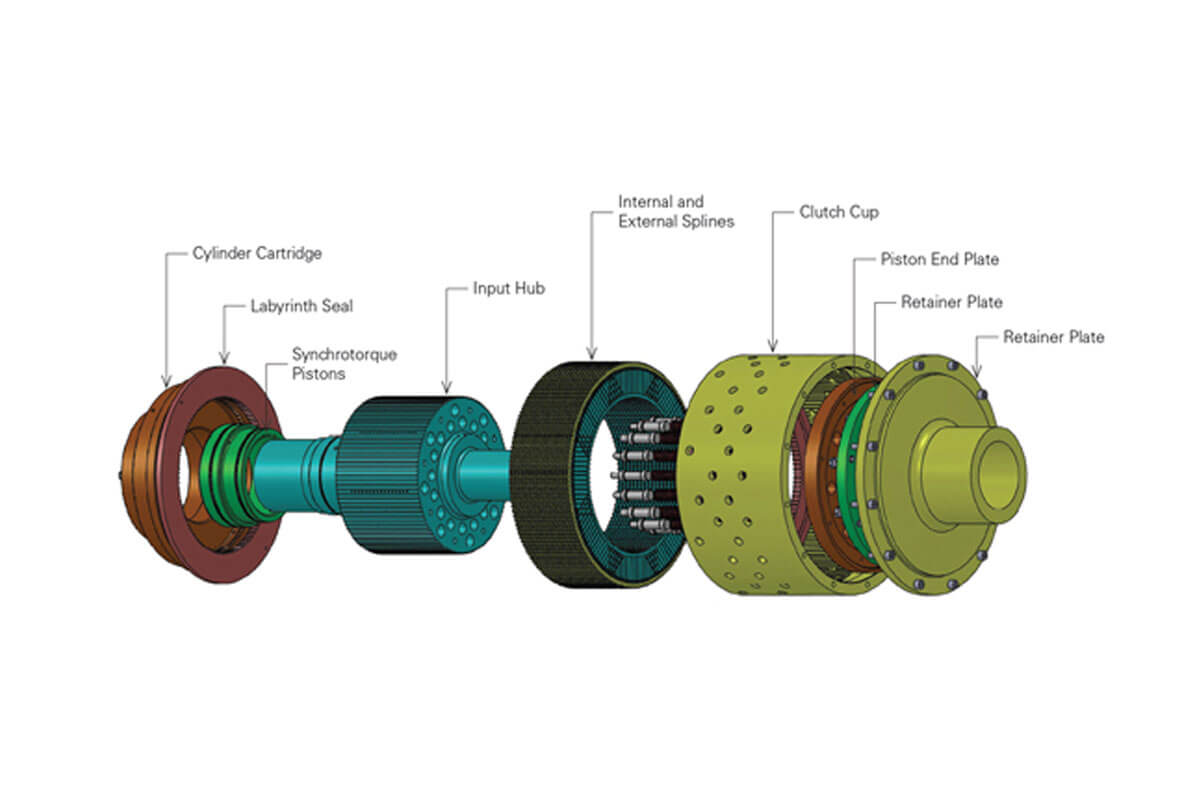

Our Synchrotorque® line of hydroviscous clutches transmits torque in proportion to a variable clamping force. Precise clamping pressure allows for output speeds equaling 100% of input speeds – maximizing energy efficiency for your operation.

TAKE CONTROL OF TORQUE TRANSMISSION WITH SYNCHROTORQUE

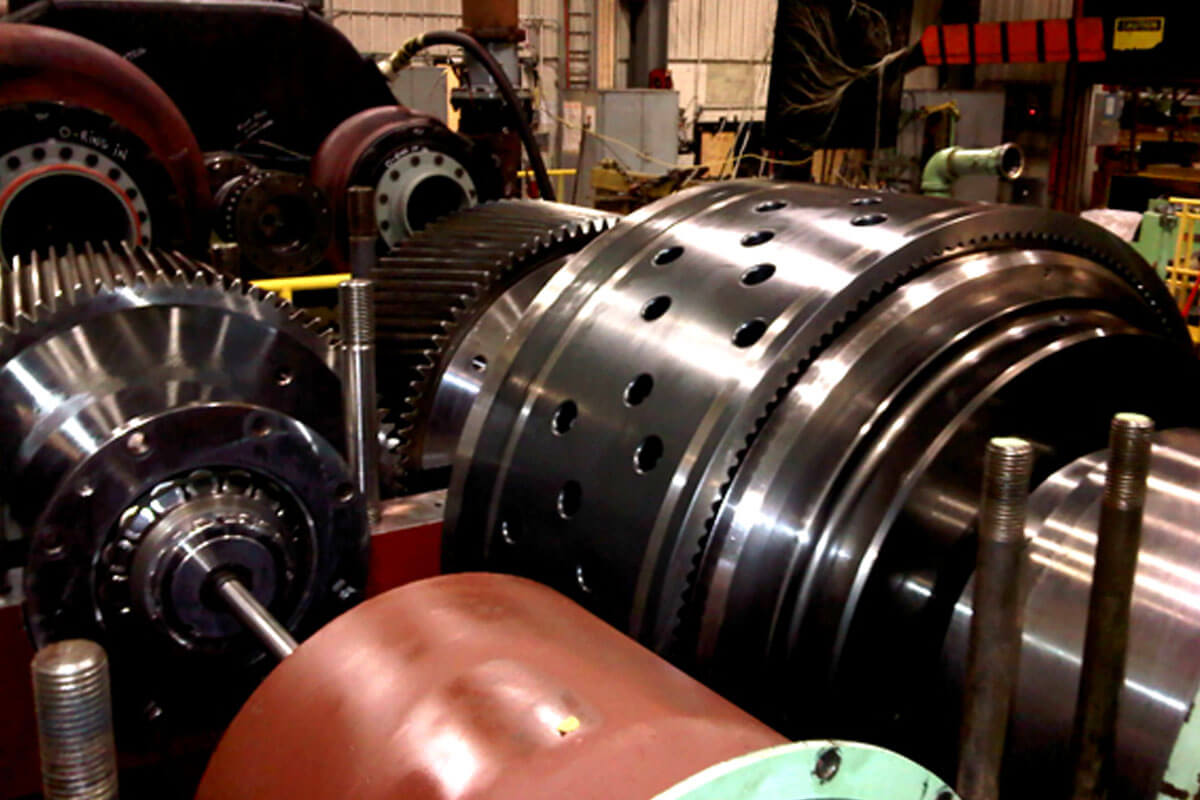

- Works for 100 to 20,000 HP applications

- Available in a range of sizes for various mounting configurations

- Eliminates fixed-slip losses

- Transmits torque in either direction

- Can remain running while disconnected from load

- Maximizes torque transfer in compact spaces

- Protects drivetrain from excessive loads with automatic torque limiting

- Designed to withstand extreme environments

THE MARK 8 SYNCHROTORQUE CONTROL SYSTEM: REDEFINING PRECISION

Ensure pinpoint-accurate control of your Synchrotorque clutches with the Mark 8. Our digital controller continuously compares input command signals to output shaft parameters, adjusting clutch clamping pressure electro-hydraulically to maintain your desired speed, torque, flow, or pressure.

First released in 1969, the Mark Series builds upon a half-century of expertise to take torque control to the next level. Discover how the Mark 8 improves upon its predecessor as the most technologically advanced controller yet.

| FEATURES AND BENEFITS | MARK VII CONTROLLER | *MARK 8 CONTROLLER |

|---|---|---|

| Simplified modular construction | ||

| I/O modules on one common bus for easier upgrades and connections | ||

| I/O modules connected with single CAN network cable to the HMI controller | ||

| Same size NEMA 4 enclosure to fit in existing footprint | ||

| Alarm log tracks up to 100 notifications, including date and time stamping | ||

| Controller maintenance troubleshooting kit for on-site repair (available for purchase) | ||

| Improved, user-friendly parameter menu screen for easy programming | ||

| Upgraded, easy-to-read color HMI touch screen display | ||

| USB flash drive or Ethernet inputs for quick updates | ||

| Single password access to assigned parameters | ||

| Built-in trending screen replaces laptop interface for fine tuning the controller |