Case Study

Onsite technical services brings plant back online in 10 days

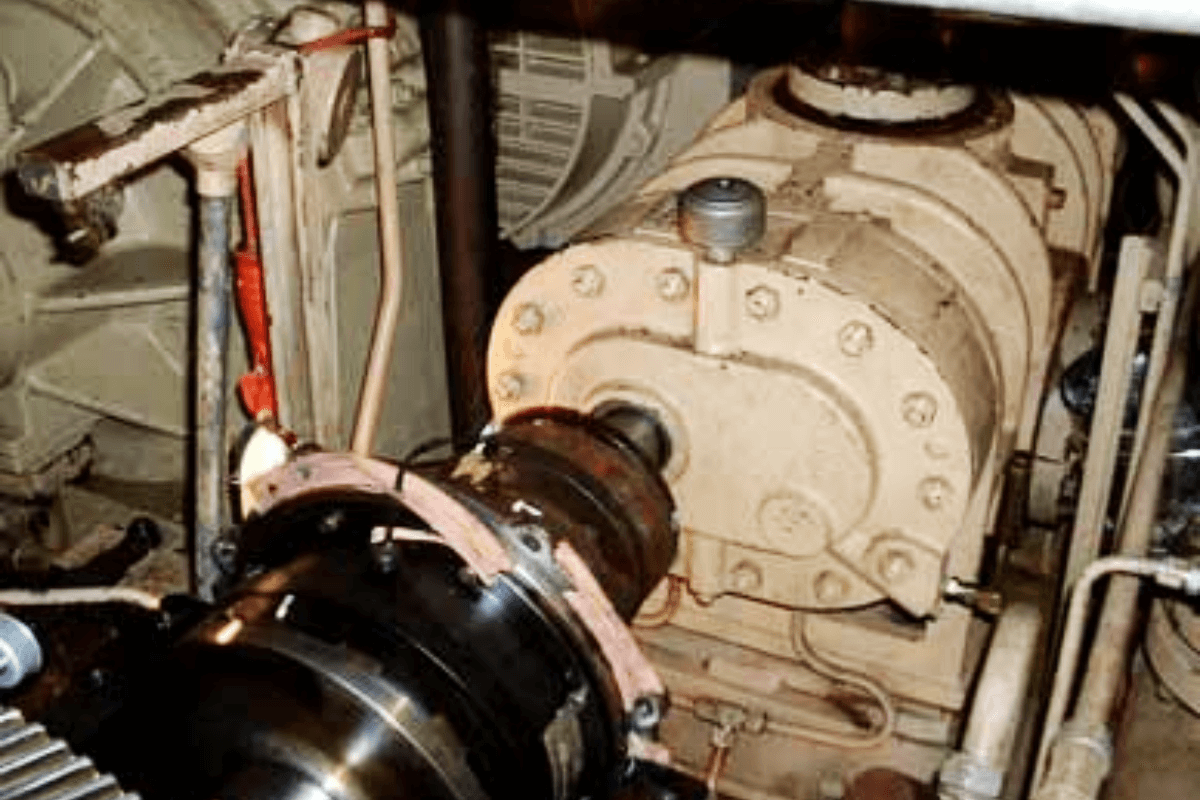

A gas-fired power plant in the Northeast Region of the United States had an unexpected problem. The accessory drive on one of its GE Frame 7 gas turbines had developed an oil leak. However, because of the turbulence in the compartment while the turbine was running, it was impossible to determine the location of the leak with any certainty.

Enter Philadelphia Gear’s OTS team. During a scheduled 14-day outage on the turbine, the team was charged with identifying the leak, correcting it, changing out all existing bearings and seals, disassembling and reassembling the entire unit as well as auxiliary equipment mounted to it, metalizing and machining scored shafts to OEM spec, and checking the housing bores for concentricity and parallelism. All of this was to be accomplished in the field in time for the unit’s restart.

Just 10 days later and four days ahead of schedule, the OTS team finished its scope of work, documented “as found” and “as left” conditions and brought the unit back online. With the turbine running at full speed, the compartment remained safe and dry, and the gearbox ran as smoothly as when it was first installed more than a decade earlier.