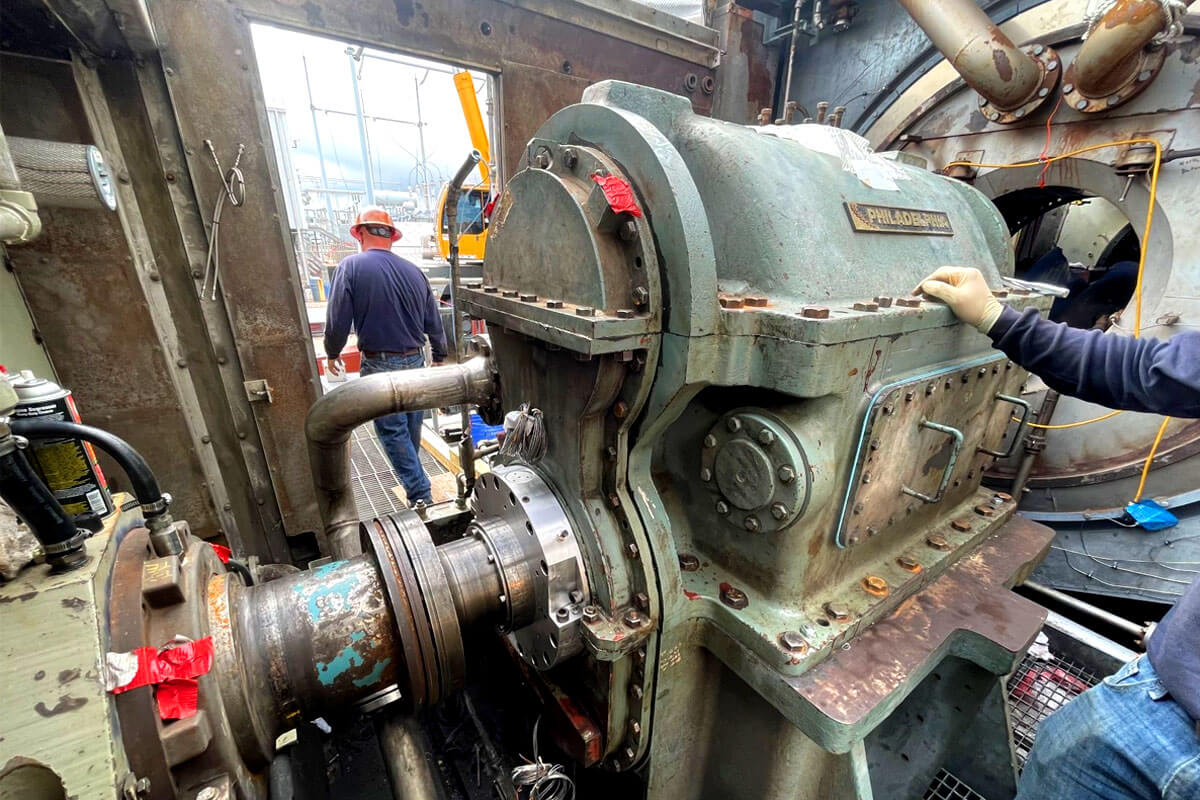

Stay focused on your core business — Philadelphia Gear® will handle your gearboxes. Our Onsite Technical Services™ (OTS) deliver a one-stop-shop solution for any industrial gearbox project, including removing and reinstalling gearboxes, rebuilding in place, reboring housings, performing rigging operations, mobilizing workforces, transporting equipment, and more.

Backed by over 130 years of mechanical expertise, our engineers apply deep understanding of your applications to handle all the heavy lifting. Reduce risk, and simplify your budgeting — Philadelphia Gear’s OTS is the one-call, one-purchase order solution for all your gearbox needs.

TERMS AND CONDITIONSDOWNLOAD OTS BROCHUREACCESS TRUSTED EMERGENCY SERVICES, 24/7

Get quick repairs and technical expertise, when you need them. Our 24/7 Technical Field Services deliver emergency support from our experienced power transmission engineers. Our team is on hand to provide detailed failure analysis assistance, as well as equipment design upgrades to keep up with your increasing process requirements.

BACKED BY A COMPLETE SUITE OF FIELD SERVICE RESOURCES

Leveraging experience with virtually every type of power transmission application, we work closely with design engineering, renewal parts, and our regional teams to provide a truly turnkey solution.

Ensure a smooth start-up with Philadelphia Gear’s unique blend of industrial gearbox design and practical operational experience.

Access support from world-class service engineers and technicians with deep expertise in repairing and upgrading existing power transmission equipment — on site or at our regional service and manufacturing facilities.

Get gearbox operational problems quickly identified and resolved, from the system down to the component level.

Access help interpreting vibration data collected on your critical rotating equipment — and avoid unscheduled equipment or process shutdowns.

Gain insights into the condition of your lubricant, plus monitoring of your industrial gearbox condition. Our team provides analyses of particulate content and concentration in your oil.

Confidently return your gearbox to service by determining the root cause of failure. Our service engineers look at the entire system — including operational loads, equipment design, equipment maintenance, and failed components — to determine the cause and a permanent corrective action.

Support changing process requirements including expanding capacity, increasing reliability, and reducing maintenance costs.

Access general and custom programs covering the maintenance and servicing of industrial gearboxes. In addition to standard training for site personnel, Philadelphia Gear develops programs for particular applications or classes of machinery, like Gear 101. Our courses balance the technical detail with the practical information necessary for proper operation, servicing, or maintenance.

GAIN THE SUPPORT TO KEEP EQUIPMENT RUNNING SMOOTHLYWhether you need an emergency solution or a long-term partnership, our expert specialists are standing by to to support your operations.

CONTACT US

Whether you need an emergency solution or a long-term partnership, our expert specialists are standing by to to support your operations.