Marine applications present some of the most complex challenges for engineered solutions, requiring high quality, reliable power transmission equipment that minimizes downtime.

Philadelphia Gear®, the U.S. Navy’s trusted partner for critical gearing applications for a century, brings the same innovative customization, rugged durability and global support to both the commercial and industrial marine sectors. Learn more about how Philadelphia Gear brings the toughest sea-tested gears to any marine application.

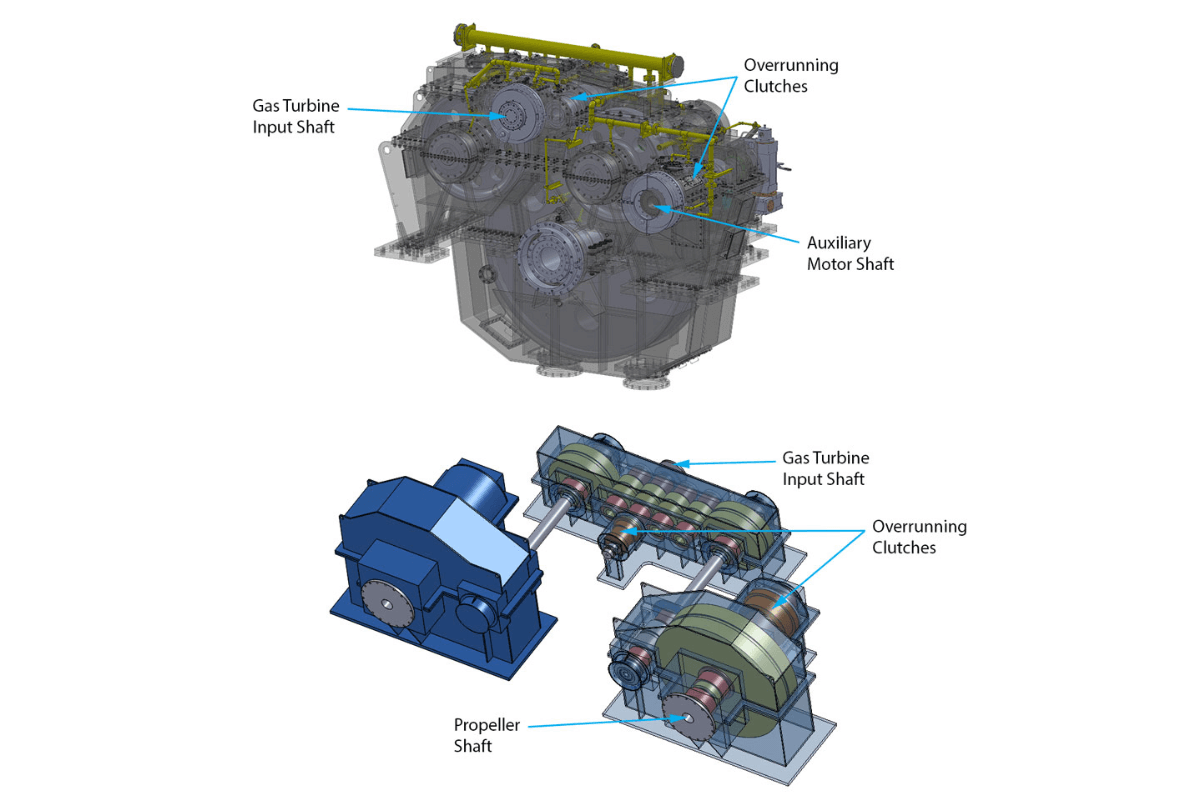

Military MarineCommercial MarineComplete support for any propulsion system configuration

- CODAG – Combined Diesel and Gas (together or separately)

- CODOG – Combined Diesel and Gas (one or the other)

- COSAG – Combined Steam and Gas (together or separately)

- CODAD – Combined Diesel and Diesel (together or separately)

- CODOD – Combined Diesel or Diesel (one or the other)

- COGAG – Combined Gas and Gas (together or separately)

- CODELAD – Combined Diesel Electric and Diesel (together or separately)

- CODELOD – Combined Diesel Electric or Diesel (one or the other)

- CODELAG – Combined Diesel Electric and Gas (together or separately)

- CODELOG – Combined Diesel Electric or Gas (one or the other)

CO = Combined

D = Diesel

G = Gas Turbine

EL= Electric Motor

O = Or (but not both at the same time)

A = And (together at the same time, or separately)